We have reworked the wooden structure of our wooden Arrow and can now offer the Arrow with a Fiberglass fuselage. 12th, October 2017 Update

The Arrow is a pure-bred aerobatics aeroplane, reconstructed in accordance with the original plan.

Arrow ARF build

30.September 2017

Todd Blose / U.S.A.

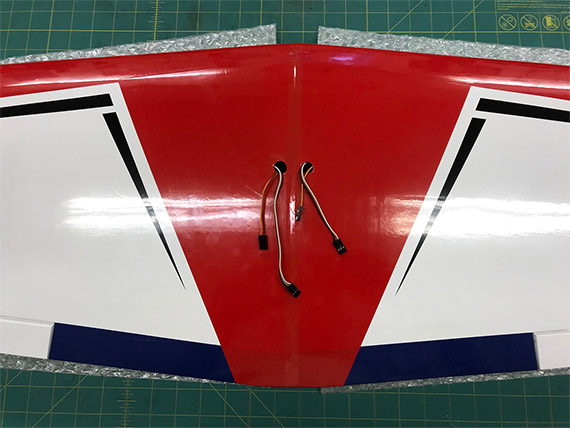

I just received the 1st Arrow ARF from Sky Aviations and I am happy to say it looks very impressive. The covering on the wings and stabs are first class and the fit to the fuse is great. It looks like the wait for the fiberglass fuselage will be well worth it and the glow version comes with added carbon fiber in the glass at the nose and wing sections for added strength. The fuse is very strong and painted in the mold and has a removal top hatch / pipe bay. I will show the weights below but it looks like this plane should come in around 8 to 81/2 lbs. on glow.

Sky Aviations will also offer an electric version that will also have the fiberglass fuselage but will not have the added carbon fiber in the nose and wing sections. I really believe that the glow version does not need it either since the fuse is so ridged. Over the next week Danny Jackson and I will be doing the build thread and getting info back to Sky Aviations on some instructions for the new Arrows that will be shipped.

We are just getting started and should have more info on the build over this weekend. The plan will be to show how we thought the easiest and best way to build this plane will be. I understand everyone will find easier ways but this is where we will start. I know this has been in the works since February but I truly believe that Sky Aviations wanted to do the right thing and that took some time. The kit comes with the standard accessories such as tank, wheels, horns, pushrods and motor mounts.

Todd Blose

In my Arrow I will using the following eq.

Motor OS Max 61 VFR

Macs Header

Novi Rossi 50042 pipe

APC 11 x 7 prop

TruTurn 2/12 Spinner

Futaba 16mz

Futaba S3071 HV servos on Ailerons and Elevators

Futaba S3102 on Throttle

SkyAviations retracts

Fuse with top and crutch 26 oz.

Wing right and left 12.6 oz ea.

Stab right and left 2.4 oz ea.

1st.October 2017

2nd.October 2017

Both panels have been completed and now they are ready to join. I installed the anti-rotation CF pins in one wing panel using 30 minepoxy and trial fit the wing halves together. The fit matches up very well and I will proceed to joining the panels using 30 min epoxy.

6st.October 2017

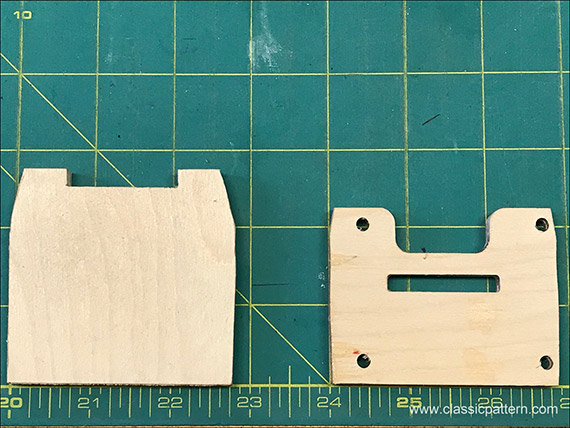

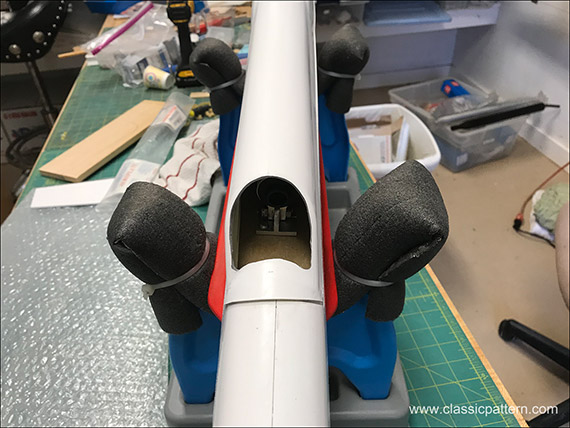

Motor mount crutch install. (New firewall and crutch will be made for the glow version)

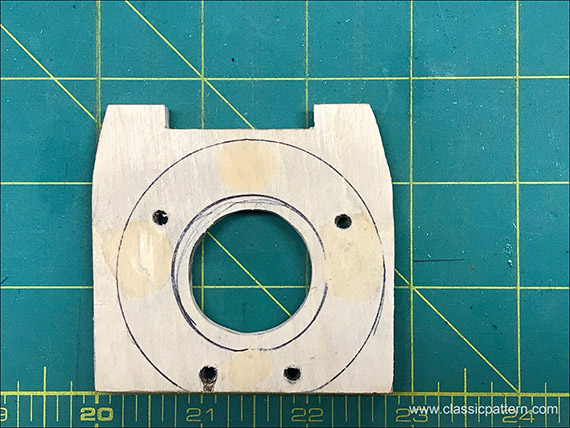

Since the Arrow was originally developed for electric power, the firewall was sized and drilled for an electric motor. A new firewall was made corresponding to the height of the raised pipe deck. The kit included beam mounts for the engine, but I decided to use a Dave Brown 60/70 radial mount. I had to trim the bottom of the mount slightly to allow the mount to be in the proper location to allow the engine to be centered on the proper thrust line. The firewall was then glued to the fuselage with epoxy.

The Arrow pipe deck and firewall that is furnished is to be used with electric power and batteries and the glow version will its own version. In order to be able to install a tank and radio equipment, the deck needs to be raised enough to accomplish this and leave enough room for the pipe. I engaged in a trial and fit exercise to arrive at a good fit that should work. Final fit will be accomplished later in the process.

10th. October 2017

This step will be done at the factory for both the glow and electric versions. I will leave this in just for a reference.

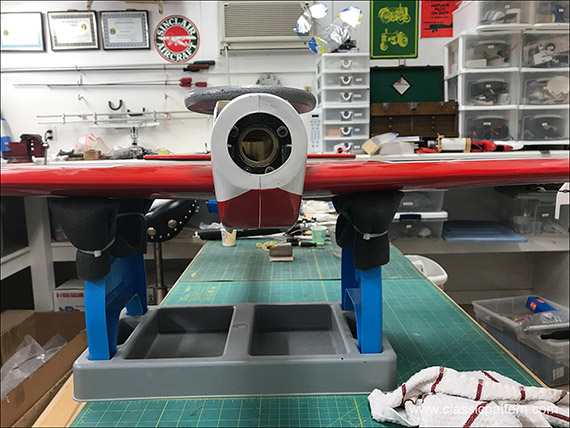

The fuselage pipe deck / crutch is now installed. Danny and I had many conversations on the best way to not only install the crutch but also an easier way to get to the tank since its always been a pain to get the tanks in through the wing opening. We decided after measuring and trying to fit the available tanks, including the one that came with the kit, a tank hatch was the best option to install and remove the tank. The tank used is a Tettra 4051, 14 oz clunk tank. The Tettra 4061 bubbless tank would work as well. If a more conventional method of installing the tank through the radio compartment was utilized, the wing saddle flange and web would have required trimming to allow installation and removal of the tank. We were not sure if this would compromise the strength of the wing saddle, so we chose the tank hatch instead. The deck was sized to allow enough room for servos in the radio compartment and sufficient room for the pipe and cooling air clearance. After the glue set, all wood that could be exposed to fuel or oil was sealed with epoxy.

11th.October 2017

Stab Install.

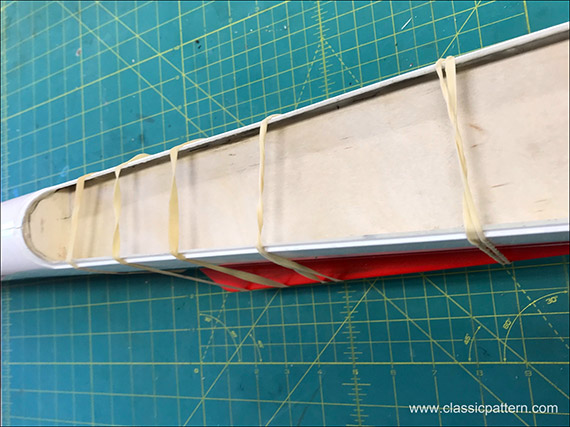

The stab assembly is now installed on the fuselage. First, the stab tubes are cut to size from the included CF tube. Then the stab halves and tubes are trial fit to the fuselage. When satisfied, prep the stab root ribs, stab tubes, and fuse where the stab halves will attach by sanding all surfaces and cleaning with appropriate solvent. Then, a sufficient quantity of slow cure epoxy should be mixed. Brush the epoxy to the root of the stab halves, fuselage, and wing tubes. Assemble the parts, check the fit, and set aside.