However, as is often the case with Super-Tigres, a number of design changes followed within a relatively short time and our present Engine Review is actually the third at-tempt to get a full report into print before the next modification rendered it out of date!

Of course, while this can be somewhat frustrating to the reviewer and, presumably, quite a problem for the distributor trying to keep his spares inventory up to date, it does at least show a commendable willingness on the part of the manufacturer to try to improve his product and this must ultimately benefit the customer. One could argue that engines ought to be 100 per cent right, from the start, but the truth is that such a happy state of affairs is seldom, if ever, achieved, since no engine, model or full size, is so perfect that it cannot be improved in the light of further experience.

The 1966 model Super-Tigre 60 R/C that is the subject of our present review is, in fact, the fourth version to pass through our hands in less than two years. None of these various models were identified by different type numbers or names, were not announced as new or improved models at the time they were introduced and since, like most current engines, the Super-Tigres do not carry serial numbers, one can differentiate between them only by noting the changes that have been made at various stages.

The original 60 was, as we have said, basically the 56-BB with the bore in-creased from 23 to 24 mm. We had one of the first batch of these for test in March 1964 but found the compression ratio excessively high. The engine was powerful but rather a handful: tricky to start, difficult to adjust for a good idle and harsh running and had a habit of throwing props. After communicating these com-plaints to the factory via the U.S. importer, we received a second sample from the manufacturer. This had, like the original, a wedge type head and no gasket, but had approximately .020 in. machined off the wedge and .015 off the squish area on the bypass side. This engine ran well, still with plenty of power and with much improved handling characteristics. We believe that few of the original type engines actually reached the market and, in any case, decompression gaskets were made available for those who wanted to run lower compression ratios on either engine. A few other small changes were also made at this early stage, including a lengthened intake boss with a thick rim at the top, while the notch in the exhaust baffle was replaced by a round hole of larger area. A new glowplug with an extra long center post, that could be reached with a normal plug clip, was also supplied.

In due course, a revised production type cylinder head was fitted. This had the original bypass side depth restored-presumably to gain maximum squish effect-but had the same wedge thickness as the modified head and a 0.6 mm. aluminum gasket was added, further reducing compression ratio. This was the model that remained available through the rest of 1964. It continued to use the large and rather complicated two-needle type carburetor originated on the 56-BB. This ingenious device, however, came in for a certain amount of criticism from multi flyers, some of whom considered it too difficult to set up properly, while others thought it needed a smaller choke area for better fuel suction and reduced consumption.

For 1965, therefore, a new and more compact carburetor was put into production. This employed a throttle system that was the same, in principle, as that fitted to most other R/C engines, namely a single needle-valve with low speed mixture compensation via a screw-controlled air-bleed. In addition, the choke area was made substantially smaller and the crank.-case boss into which the carburetor was fitted, was shortened. This engine had a slightly lower maximum output than the earlier models.

The 1966 version of the Super-Tigre 60 R/C is identical, outwardly, with the engine just described but, again, has a number of internal mods. Firstly, the cylinder head has been changed once more and now features a hemi-spherical combustion chamber. Either one, or two, 0.6 mm. gaskets can be used. Secondly and thirdly (presumably to regain some of the power lost in making the engine more tractable) the carburetor intake has been opened out again (8 mm. on the 1964 engine, 6.5 mm for the 1965 and now 7.0 mm) and the bypass has been widened by machining two flutes in the casting-a la Series 64 K&B 29R. Incidentally, thanks to the lower weight of the small carburetor, this engine is an ounce lighter than the 1964 model.

Much of designer/manufacturer Jaures Garofali’s past research and development work on model engines has been in the control-line speed field and most Super-Tigre competition successes, including several world championship and international events, have been in the FAI speed and freeflight categories where high power is of paramount importance. A certain amount of “speed thinking” seems to have filtered through to the 51-56-60 series also-notably in the intake porting. These were the first R/C engines to use a 15 mm. shaft, allowing a very large bore gas pass-age and a big valve port, timed to stay open for 200 degrees of crank rotation. Actually, as measured on the current 60, the valve opens at 28 deg. ABDC and closes at 50. deg. ATDC. Not every R/C engine designer might agree that such a lengthy intake period or such relatively late closure is strictly necessary on an engine delivering its peak output at 11,000 rpm. Cylinder porting features four exhaust ports and four bypass ports of identical size (5.5 x 5.0 mm.) and spacing. Port timing, as measured on the latest 60`. is 70-70 exhaust and 61-61 bypass.

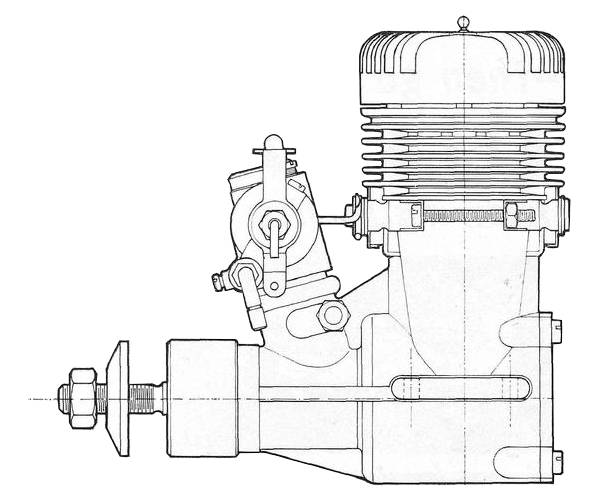

The construction of the 60-R/C follows standard Super-Tigre practice. The crank-case/cylinder-block/front-housing is a one-piece pressure casting in silicon-aluminum alloy, liberally machine finished to ensure accurate location of related components. The nickel-chrome steel crankshaft has a 7 mm. hollow crankpin, an 8 mm. thick crankweb and is counterbalanced by having the web flanks cut away each side of the pin. The shaft runs in one 15×32 mm. ball journal bearing at the rear and a 7×19 mm. ball-bearing at the front where it carries a machined aluminum prop driver on an aluminum split taper collet. The driver is recessed at the back to partially enclose the end of the front bearing housing. Be-yond this, the shaft is stepped down for a standard 1/4-in. American N.F. thread.

The cylinder sleeve is of leaded steel with a chromed bore and has fairly thin walls (1.0 mm.-.039 in.). It is located in the usual way by a flange at the top and, tightly fitted in the casting, can be extracted by heating the casting to 250-300 deg.F. (It is necessary to extract the sleeve before the piston, rod, shaft and bearings can be removed.) The piston is a permanent mold casting in aluminum with two compression rings. It is flat topped except for an orthodox straight baffle on the by-pass side and carries a 6 mm.dia. hollow, hardened tubular wrist-pin with aluminum pads. The conrod is machined from dural bar stock, is unbushed and has a single oil hole at the big end. The cylinder head is deeply finned, with a centrally located plug, and is secured to the cylinder block with six screws. Incidentally, the block is relieved 0.15 mm. for a depth of 7 mm., presumably to allow for any contraction due to head screw tightening which might otherwise distort the liner.

The carburetor body is of aluminum and carries a ground steel throttle barrel. A spraybar type needle-valve assembly is used and passes axially through the throttle barrel but does not rotate with it. Throttle linkage and fuel inlet are both on the right-hand side and cannot be re-versed, unless the coupled exhaust restrictor is dispensed with (as when using a muffler) in which case the complete carburetor could, if necessary, be turned through 180 degrees. The carburetor is neatly held in place in the intake boss by a-cotter pin and nut and seats on a rubber gasket. The exhaust restrictor is of the semi-rotary type and is contained in a separate, aluminum housing secured by steel straps around the cylinder. .

Like most ringed engines, the 60 R/C required only a short break-in. Our test model 60 R/C came direct from the factory and had had some running prior to dispatch. We gave the engine a further one hour and followed this by checking running qualities with one and two gaskets, different plugs and the effects of two types of mufflers, before running tests on prop speeds and power output.

In general, power output was fairly closely matched to that of a “large carburetor” type ST 60, tested eighteen months ago and reached just over 0.87 bhp at 11,000 rpm. Allowing for the slightly more favorable weather conditions of the present test, maximum torque was a little higher, but was a trifle less at speeds above 10-11,000 rpm. We may assume that the combination of smaller choke area, lower compression ratio and widened bypass of the latest model are responsible for the slight changes in the course of the torque and power curves.

Starting was quick at all times and cold starts with the throttle in the idling Position were quite feasible. However, there was a tendency for the ‘Tigre to start back-wards with the throttle closed or to occasionally kick its prop loose. Both these characteristics were eliminated by using two head gaskets instead of one and we found that a lower idling speed could then be obtained also.

The bleed hole for admitting extra air at idling speed is very small on the Super-Tigre and we found this inadequate. It was impossible, even with the adjusting screw backed off, to get the idling mixture lean enough for reliable idling below about 3200 rpm when the needle-valve was adjusted to the optimum full-throttle setting, unless the plug lead was re-connected. This prompted us to try other plugs and we were able to get the idling speed a little lower by substituting a K&B idle-bar plug. It is, however, a simple matter to enlarge the existing bleed hole. This is something that was also found desirable on some earlier models of these engines.

The best prop sizes for extracting maxi-mum performance from the 60 R/C are probably 11×7, 12×6 and 12×5 depending on model type. An 11×6 roughly coincides with the engine’s bhp peaking speed (11,000 rpm) on the ground, but will obvious-ly run beyond it in the air. We found that the 60 ran quite smoothly on a variety of props from 14×6 down to 11×3. There was a slight power loss on reaching running temperature on the largest size props, equivalent to a drop of 100-200 rpm, but, when lightly loaded, the Tigre picked up a couple of hundred rpm from cold. All previous models of this Super-Tigre series ran rather hat and the latest 60 was no exception.

The manufacturer has produced proto-type mufflers for various Super-Tigre engines and a production version suitable for the 60 R/C is expected in the near future. Since these were not available at the time of testing, we ran some tests using the Gee-Dee Pike (British) and Koelliker (Swiss) mufflers currently marketed for the Super-Tigre 51-60 models. Neither of these substantially affected performance up to 9000 rpm or so, but they did curtail the top end rather more noticeably, reducing the peak bhp by 12-15 percent and peaking speed by approximately 1000 rpm. Both, however, provided effective and worthwhile muffling.

The Super-Tigre 60 R/C continues to be one of the most internationally popular multi engines and justifiably so. It is powerful, easy starting and finely made from top quality materials.